How many kinds of plastic bags are there? What are the industrial uses of each?

Apr 28, 2025

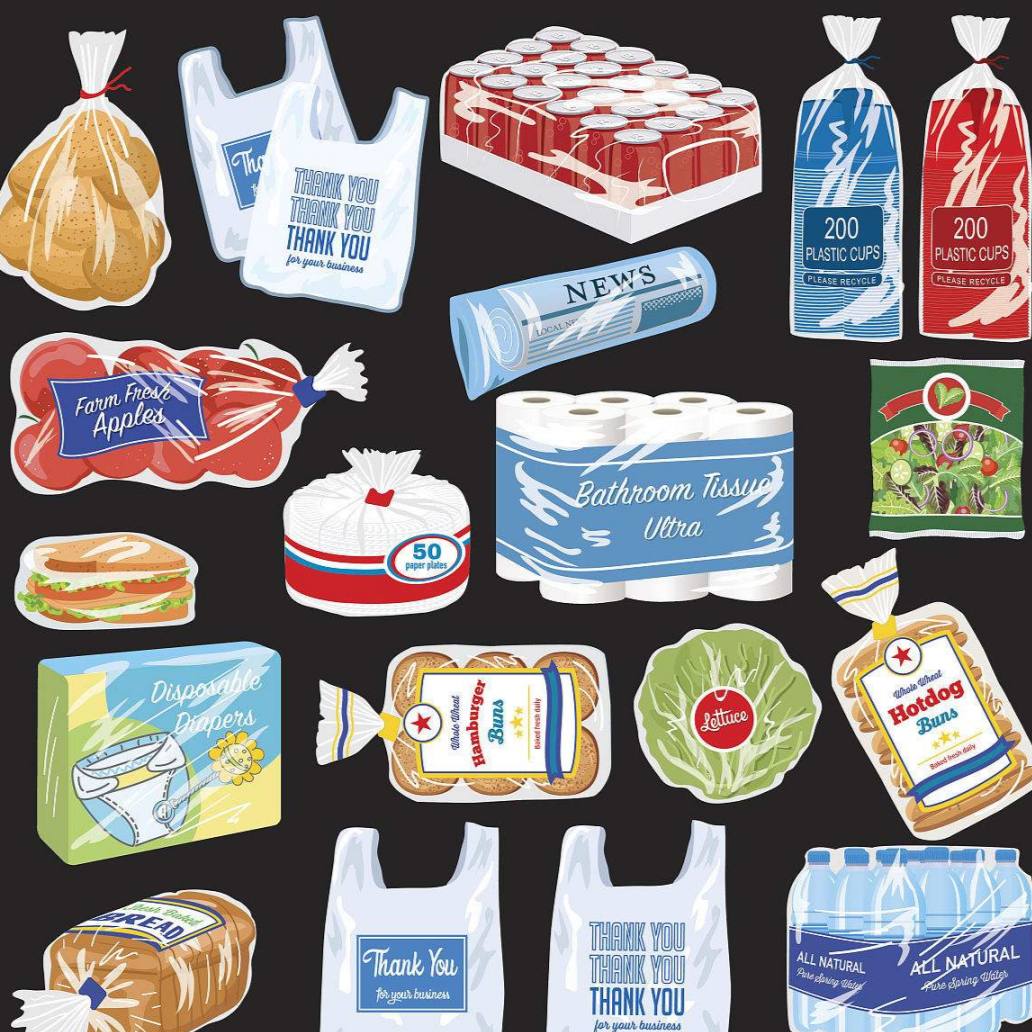

Different plastic bags can meet different use needs. How many kinds of plastic bags are there? What are the industrial uses of each? When you know the answers to these two questions, you basically understand why the plastic bag market is so colorful, repeatedly banned.

Vest bag: the shape is similar to the vest that people wear, called vest bag and vest bag, convenient bag and so on. Mainly used in supermarkets, department stores, shopping malls, convenience stores, wholesale markets, grocery stores and so on. Generally, PO is the main production material, which is simple to make and widely used.

Handbag: also known as handbag shopping bag , advertising gift bag. It is generally made of PO (HDPE high density polyethylene) or PE (LDPE low density polyethylene) plastic bags. These two materials are non-toxic, tasteless, hygienic and safe. Often used in clothing, gifts, ornaments, stationery and other industries, the shape of the design is fashionable, convenient and good-looking, loved by users.

Flat pocket: generally used for industrial packaging, due to different sealing methods are also made into Yuan line bag (R bag), this is one of the plastic bag manufacturers often customized plastic bag, but also one of the larger amount of plastic bag.

Self-adhesive bag : also known as sticky pocket, self-adhesive plastic bag. Mainly used in stationery, ornaments, food and other industries. OPP, PE as the main raw materials, self-adhesive bag printing effect is very good, so it is suitable for processing into beautiful product packaging, the product is very transparent, is the most transparent plastic bag type, the product is relatively brittle, toughness is not good enough, easy to tear, relatively large volume or heavy weight, generally add environmental protection edge, to prevent cracking.

Card head bag: also called mother bag. It is generally divided into two parts, one is the bag and the other is the card head. The card head is equivalent to an "advertising space" used to promote or attract consumers' desire to buy. Using OPP, PE as the main raw materials, product characteristics and the principle of sealing bags.

Bone bag: good sealing, acid and alkali resistance, non-toxic. Dustproof, moisture-proof and leakproof. Hardware, jewelry, electronics, medicine, supermarket, snack shop, tea, stationery, toys, printing, leather goods and other industries. PE bone bag can be used to hold food, which can prevent moisture-afraid food and medicinal materials from being softened by moisture, maintain the essential taste, and can also be used to hold tea.

Hook bag: it is divided into inclined hanging bag and flat hanging bag. Common in the clothing industry, such as major brand clothing stores, dry cleaners, set in suits, jackets and other clothes outside, the main role is to prevent ash, dust, waterproof and so on.

Bubble bag: the use of low density polyethylene processing, is a widely used transparent flexible packaging material, a wide range of uses. Because the middle layer of plastic film is full of air, light body, elastic, sound insulation, heat insulation, shockproof, anti-wear performance, but also waterproof, moisture-proof, pressure resistance. It is mostly used in product transportation.

Square bag: also known as square bottom bag, generally by LDPE (high pressure low density) and LLDPE (linear low density) through the film blowing machine blowing out of the barrel, and then made into plastic packaging bag, the material feel is soft, the thickness can be adjusted freely. According to the production process can be divided into flat pocket, folding bag and square bottom bag; According to whether printing can be divided into blank bag and printing bag; According to whether antistatic can be divided into ordinary and antistatic two.

Express bag: including express plastic bag, express bubble bag, express bone bag, etc. At present, there are two types of commonly used in the market: one is the new material express bag (SF express bag, federal express bag, home delivery, etc.), the other is the recycled material express bag (mostly used by small express companies).

Shrink bag: also called shrink wrap. Common in food stalls, restaurants, restaurants and other places. With high transparency, shrinkage performance, heat sealing performance. It has the characteristics of good toughness, antistatic, cold resistance and so on. It is a non-toxic, safe and reliable soft shrink film. It is useful in many fields and is one of the most common plastic bags in our life.

In addition to the types of plastic bags mentioned above, there are composite bags, aluminum foil bags, biodegradable bags, inflatable bags, etc. These plastic bags in my clothing, food, housing and transportation can participate in the use of large, natural prosperity of the market.

Read More